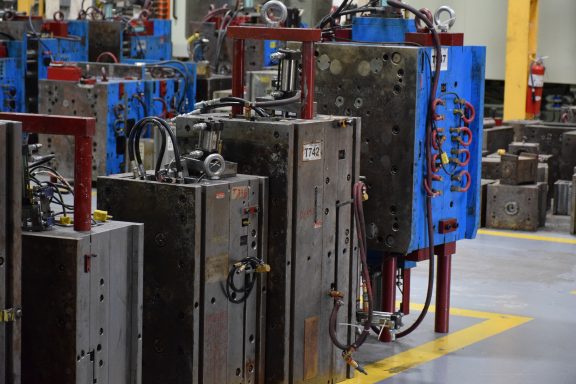

On-Site Tooling

Our dedicated and experienced on-site tooling department can maintain and modify your tools to fit your specifications. Our processes ensure cost-effective and high-quality solutions. We will work with you to find solutions to problems that may cause your tooling to work inefficiently or not at all.

When your tool needs to see a specialist, we have a variety of partners that we will hand the work off to for a seamless experience for you.

The most common issues we address on a day to day basis are:

- Diagnosing tool failure

- Replacing springs

- Replacing pins

- Lubing components

- Cleaning, stoning, and polishing mold surface

- Engineering changes

- General preventive maintenance

- Modifying venting system to improve flow and decrease burning and voids

- Modifying gate systems to improve flow and address flowlines

- Improving tool cooling system

- Improving parting lines

- Improving tool seal-offs

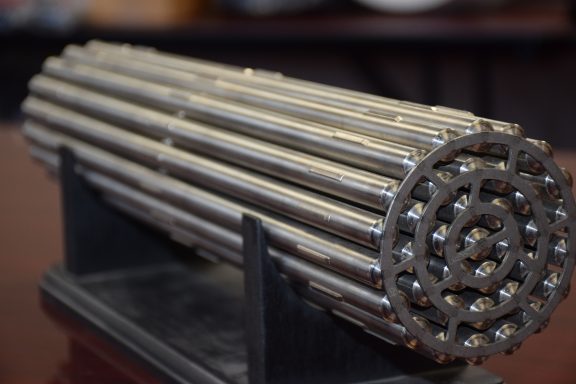

Behind the scenes, we also build supporting fixtures and gauges for:

- Part cooling

- Supporting automation

- Milling and lathing

- De-gating

- Dimensional verification